私たちは

リサイクル事業を通じて、

地球環境に優しい

社会創りへの貢献を

目指します。

For an environmentally friendly society.

私たち高山化成は限りある資源を有効利用するリサイクル事業を通じて、

地球環境に優しい社会創りへの貢献を目指します。

エコロジーへの挑戦は21世紀の社会において人類共通の大きなテーマです。

高山化成は、自然環境を守るため限りある資源を有効に利用することを使命として、

廃棄物を活用するリサイクル事業を展開しております。

塩化ビニール、ゴム、オレフィン系樹脂などの廃材を用いて、

快適空間を創造する遮音材、制振材などの研究、企画、開発、生産を手がけています。

自然に優しい環境保全事業を通じて21世紀にふさわしい企業として歩み続けていきます。

We here at Takayama Kasei believe that the most important aspect for us humans to prosper is to create a greener and healthier earth for us to live on.

With environmental issues being high on the agenda lately, we believe that everyone needs to do their part in our common endeavor for a brighter future. Through recycling and re-using we are aiming to utilize our earths limited natural resources as efficiently as possible and not let anything go to waste.

We have managed to develop a way for us to use recycled PVC, rubber and olefin resin to manufacture state-of-the-art flooring tiles and sound insulating material.

We will continue our journey through the 21st century with pride, not only thanks to our products, but also because of what we stand for. To create a better earth, for all of us.

代表取締役 高山 了俊 CEO Noritoshi Takayama

PUBLISHED MEDIA

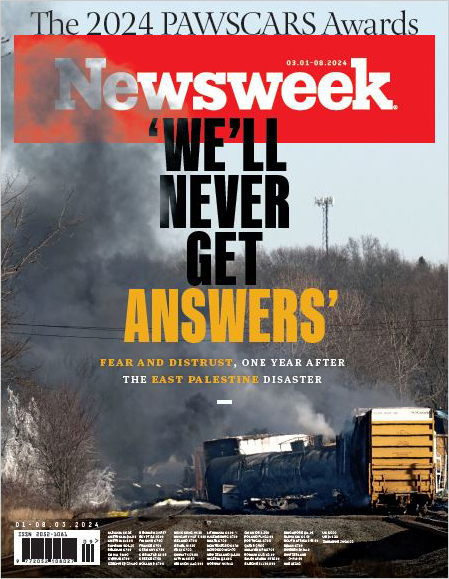

Newsweek International March 01-08 2024

"Takayama Kasei Sets Sights on a Recycling-Oriented Society", Newsweek International March 01-08 2024, February 24, 2024, Newsweek

*Newsweek記事日本語訳

循環型社会を目指す高山化成

1965年創業のこの会社はリサイクル材料を用いてプレミアムな品質の床用タイルと遮音製品を製造することに専心している。

高山化成はリサイクル材料を使用して最先端の製品を生み出す日本のメーカーです。同社は幅広い建物のタイプに適した床タイルと防音材の製造を専門としています。

「当社はリサイクル材をタイルや遮音材に利用する日本企業の一つです。」と社長の高山了俊氏が言明する。

高山化成の製品は環境に優しいだけでなく、日本の人口動態の変化も念頭に置いて作られています。

国内人口の減少に伴い、熟練した人もそうでない人も安心して施工できるよう、当社の製品は慎重に設計されています。

高山氏はまた、「高山化成が用いているリサイクル材料が卓越した品質への取り組みに影響を与えないことも強調しています。JIS が整備されており、当社のような企業が認証を取得しています。JISは再生材ではないバージン材を対象に制定された規格でしたが、当社はその基準をクリアしました。当社はより環境に優しい未来を目指して、循環経済を促進する取り組みを強化しています。当社の床タイルには、リサイクルされたプラスチックと充填剤の石の粉末を使用しています。このフィラーは山奥から採取されたバージン素材です。新しい製品ラインとして他の廃棄物を使用したラインナップを拡大する予定です。それが私たちの研究開発の現在の焦点であり、ほぼ完了しています。自社製品の世界展開にも取り組み、地元企業との販売提携を模索しています。私たちは、現代日本の生活感や防音性のニーズといったニッチな市場に焦点を当てたいと考えています。」と述べています。

COMPANY OVERVIEW

- 社名 Company name

- 株式会社 高山化成 Takayama Kasei Co. ,Ltd.

- 代表取締役 CEO

- 高山 了俊 Noritoshi Takayama

- 資本金 Capital

- 6,000万円 60 000 000 JPY

- 創業 Founded

- 1965年4月 April, 1965

- 所在地 Head office

-

〒581-0039

大阪府八尾市太田新町3-133

TEL : 072-949-6510(代)

FAX : 072-948-1043 581-0039

Osaka-fu, Yao-shi, Otashinmachi 3-133 (Japan)

TEL : +81-72 949 6510

FAX : +81-72 948 1043

- 工場 Factory

-

〒518-0127

三重県伊賀市山出100-1

TEL : 0595-26-7373

FAX : 0595-26-7388 518-0127

Mie-ken, Iga-shi, Yamade 100-1 (Japan)

TEL : +81-59 526 7373

FAX : +81-59 526 7388

- 敷地面積 Site area

- 約5,000坪(16,460.31㎡) About 5,000 tsubo (16,460.31㎡)

COMPANY HISTORY

- 1965年4月 April, 1965

- 「高山化成工業所」を大阪府に創業 With a capital of 10 million JPY and the goal of creating top class PVC products Takayama Kasei Industries Co. ,Ltd. was founded in Osaka, Japan.

- 1971年1月 January, 1971

-

大阪府八尾市(現在地)に本社機能を移転。トヨタ向け自動車用遮音シートの生産を開始

Moved to Yao City, just outside of Osaka.

Began the production of sound insulating materials for cars.

- 1976年8月 August, 1976

- 株式会社高山化成工業所を塩化ビニール製品の製造・販売を目的に資本金1,000万円にて設立 Established Takayama Kasei Industries Co., Ltd. with a capital of 10 million yen for the purpose of manufacturing and selling vinyl chloride products.

- 1985年8月 August, 1985

- シーティング部門の生産強化のため、大阪府八尾市に新工場建設 Established a factory next to the head office in Yao City.

- 1987年1月 January, 1987

- 建材部工場を八尾市(本社敷地内)に建設 Began the manufacturing of building material.

- 1987年12月 December, 1987

- (株)高山化成工業所100%出資の「株式会社 泰邦」を設立(現連結子会社) Established the consolidated subsidiary Taiho Co.,Ltd

- 1988年12月 December, 1988

- 「株式会社 高山化成」に社名を変更 Changed name from Takayama Kasei Industries Co.,Ltd to Takayama Kasei Co.,Ltd.

- 1989年5月 May, 1989

- 建材部内にラミネート部門を設置 塩ビタイルのラミネート生産を開始 Began the production of laminated products.

- 1999年5月 May, 1999

- 蝶理株式会社との合弁により中華人民共和国・青島市に青島華蝶塑膠制品有限公司を設立 Established [Qingdao Huadie Plastic Products Co., Ltd.] as a joint venture with Chori Co.,Ltd in Qingdao, China.

- 2000年7月 June, 2000

- ISO9002(当時)の認証取得 大阪府の中小企業経営革新の認証取得 Acquired ISO9002 [Innovative management for small-medium sized enterprises]

- 2001年1月 January, 2001

- 製造部門強化の為、三重県上野市(現伊賀市)に工場を設立 Opening of new factory in Iga City.

- 2008年9月 September, 2008

- 伊賀工場の設立に伴い、製造ライン統合の為、青島華蝶塑膠制品有限公司を伊賀工場へ吸収 For a smoother running production line all production was moved to the new factory in Iga City.

- 2009年6月 June, 2009

- 環境マネジメントシステム認証(ISO14001)を伊賀工場で取得 Acquired ISO14001 [Environmental management system] at the Iga factory.

- 2009年7月 July, 2009

- 資本金を6000万円に増資 Increased its capital from 10 million to 60 million JPY.

- 2011年8月 August, 2011

-

ISO9001/14001の両マネジメントシステムを統合し、全社で運用を開始

労働安全マネジメントシステム(引用企画:厚生労働省告示第113号)運用を開始 Management systems ISO9001/14001 was integrated.

lso establish the labour safety management system (normative references: health and welfare labour notification No. 117).

- 2012年5月 May. 2012

- 労働安全マネジメントシステムの認証を取得 Acquired the occupational safety management system certification.

- 2013年10月 October, 2013

- 中小企業庁・ものづくり中小企業支援 承認取得 Recieved “Manufacturers SME support” from Small and Medium Enterprises agency.

- 2019年2月 February, 2019

- 中小企業庁・ものづくり中小企業支援 4回目承認取得 Recieved the 4th “Manufacturers SME support” from Small and Medium Enterprises agency.

- 2019年11月 November, 2019

- 品質・環境・労働安全マネジメントシステムについて、2019年11月より自社独自規格へ移行、外部認証を終了 Regarding quality, environment, and occupational safety management systems, from November 2019, we transitioned to our own standards and completed external certification.

BASIC POLICY

地球や社会のために

ずっと、もっと、

続けていきたい。

For our earth, and its people.

I want to keep doing it all the time.

真撃に、積極的に、リサイクルに向き合う、をモットーとして、

限りある資源を有効利用するリサイクル事業を通じて、

環境と人にとっての必然を見据え、社会への貢献を目指します。

We aim to re-use and recycle as much material as we possibly can in order to give our earth time to recover and become a better place for all of us to live on.

リサイクル資源を用いた、地球と人に優しい防音遮音・床材製品を通じて、

静けさや安らぎのある空間を提供し、アメニティ空間の創造に貢献します。

労働安全衛生が全従業員の共通の最重要課題のひとつであることを認識し、

安心して仕事ができる快適な職場づくりを推進します。

Through challenging, yet rewarding, jobs we ensure our staff both a professional as well as a personal growth. We believe that the health and safety of our staff is the most important thing in our pursuit of success, we therefore regularly conduct health examinations and try to improve the working conditions in our factory.

COURSE OF ACTION

-

顧客のニーズや期待にこたえるために品質マニュアルの実行を徹底します。

-

環境・労働安全衛生に関する法令の遵守

国・地方自治体の法規制、条例及びその他の要求事項(事業場の安全衛生管理規定を含む)を尊守します。

-

資源・エネルギーの効率的活動

省資源、省エネルギー活動を積極的に推進し、資源、エネルギーの効率的利用に努めます。

-

廃棄物の減量推進

廃棄物の適正管理、適正処理により、廃棄物の量的減量を推進します。

-

環境に配慮したエコ対応の製品の開発を進めます。

-

周辺住民への影響を配慮

水質汚濁・大気汚染を防止し、悪臭・騒音・振動により従業員や周辺住民に影響を与えないよう配慮します。

-

労働安全衛生リスクの低減に取り組み、労働災害の防止を図ります。

構築した環境マネジメントシステム(EMS)の効果的な運用を行い、緊急時の対応を含め汚染の防止に努め継続的改善を図るとともに、環境汚染の予防に努めます。

-

労働者の協力の下に、安全衛生活動を促進します。

-

見直し

事業活動全般の環境影響評価を行い、統合方針、統合目的、統合目標を定め、年1回社長が見直しを実施します。

-

継続的改善

構築した統合マネジメントシステムの効果的な運用を行い、顧客満足を維持・向上させ、有効性を維持できるよう継続的改善を図るとともに、緊急時の対応を含め環境汚染の予防に努め、労働安全衛生に関する措置を適切に実施します。

-

統合方針の周知と公開

組織で働く全員に統合方針を周知徹底させ、品質・環境・労働安全衛生に関する教育・訓練などを通じて社員の意識向上を図るとともに、統合方針を社外に公開します。

-

We are following all the local and national rules and regulations, as well as the health and safety management provisions on the workplace.

-

We move forward with efficient use of our resources and energy.

-

We push forward by reducing our waste with proper management and disposal.

-

We strive to develop a product that is eco-friendly both in its use and production.

-

We do not let our neighbours get disturbed by any smell, noise or pollution from our factory.

-

We enforce annual reexamination of ongoing projects to evaluate environmental effects and set policies, purpose and goals for the coming year.

-

We only use machines and products of the highest quality in order to ensure a safe and sound workplace as well as top quality products.

-

We enforce every co-worker to know our environmental policy thoroughly and improve their consciousness by environmental education and training.

-

We do everything in our power to meet our customers needs and demands.